MGKF74 Series CNC Vertical Spindle Compound Grinding Center

MGKF74 Series CNC Vertical Spindle Compound Grinding Center

Technical Proposal

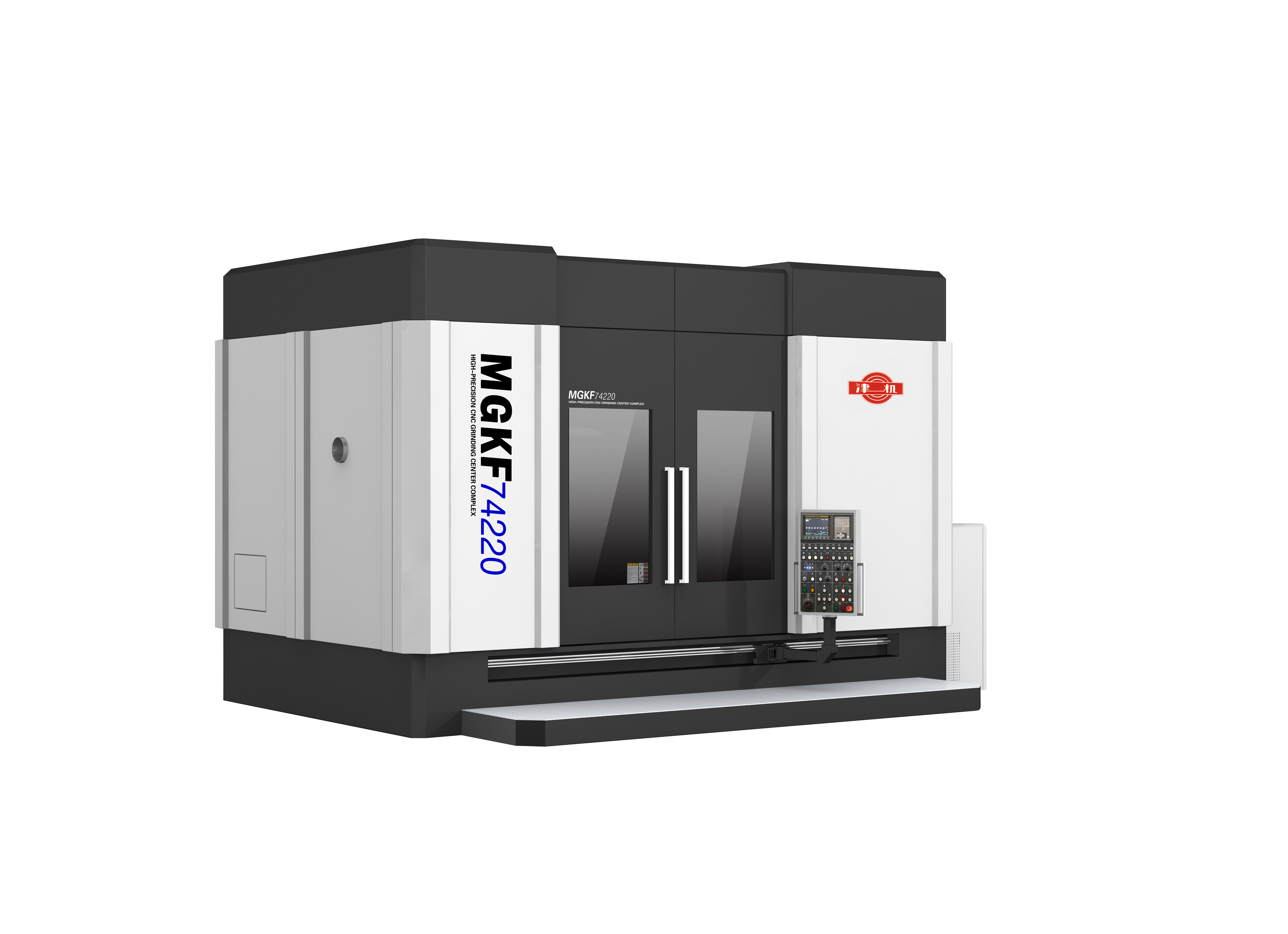

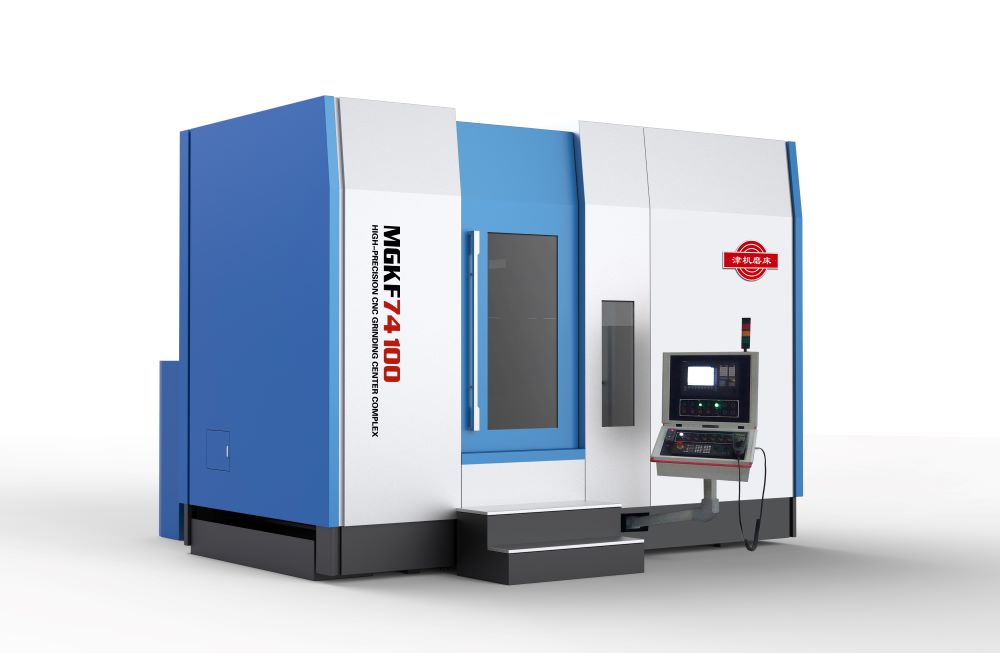

The MGKF74 series high-precision CNC compound vertical grinding centers characterized by modern design, excellent rigidity, and good practicality, achieving a high integration of high precision, high speed, and performance. This series of grinding machines can perform grinding operations for holes, external cylindrical surfaces, and flat surfaces at one chuck, automatic tool change, automatic workpiece measurement, and online dynamic balancing system of grinding wheels. Thus, a wide scope of applications is available.

1. Machine layout

The MGKF74 series is an eight-CNC-axis vertical grinding center that uses Siemens 840sl system.

The major components of this machine tool are the bed and the column. The machine tool bed consists of front and rear beds, and the column is placed on it for longitudinal shift. The carriage drives the grinding head and the turret to move vertically on the column, and the round table rotates at the front of the bed. The turret can make the grinding head realize continuous indexing and is equipped with an automatic measurement system. The four-position tool magazine is located on the right side of the bed and can achieve automatic tool change. The wheel dresser is located between the round table and the tool magazine. The electrical device, hydraulic device, and cooling device are located at the rear of the machine tool. The electrical control box is fixed on the front right side of the bed.

This layout has the following advantages:

1)The machine tool adopts an internationally advanced layout, overcomes the deformation of the gantry-type layout crossbeam, minimizes the large assembly surface, makes the large structure more compact, reduces the installation and adjustment process, increases the overall rigidity and stability of the machine tool, and has a beautiful shape with a small footprint.

2)The machine tool is mainly used for processing and grinding aviation engine shafts and disk-type parts, and can process materials such as titanium alloys, stainless steel, and high-temperature alloys. The machine tool can also be used for the processing of various circular disk-type and gear-type parts in industries such as bearings, molds, automobiles, aerospace, ships, and locomotives.

2. Machine main specification parameters

Worktable diameter | mm | 600(Example) | According to user needs |

Max. outer diameter | mm | 600 | According to user needs |

Max. rotating diameter | mm | 700 | |

Hole diameter range | mm | 60-500 | |

Max. height | mm | 400 | The height is 100 when the hole diameter is 200 |

Worktable speed and power | r/min | 2~150 | |

Wheel head speed and power | r/min | 1000~9000 | 15KW |

Swiveling range | ±90º | ||

Max. load | Kg | 500 | |

X/Y-axis max travel | mm | 1000/600 | |

X/Z-axis move speed | mm/min | 0~6000 | |

X/Y-axis resolution | mm | 0.001 | |

B-axis resolution | º | 1/1000º | |

B-axis indexing accuracy | “ | 3.6” |

3. Main accuracy of machine

Worktable radial runout | mm | 0.002 |

Worktable axial runout | mm | 0.002 |

grinding wheel spindle radial runout | mm | 0.002 |

Griding wheel spindle axial runout | mm | 0.002 |

X/Z-axis positioning accuracy | mm | 0.008 |

X/Z-axis repeatability | mm | 0.004 |

4. Machining accuracy

1) Machining workpieces roundness: ≤0.004 mm

2) Machining workpieces cylindricity: ≤0.006/300 mm

3) Machining flatness of end face: ≤0.005 mm

4) Perpendicularity of the end facing the inner and outer circle: ≤0.01 mm

5) Surface roughness Ra: ≤0.40 um

5. Main customer

1.洛阳世必爱特种轴承有限公司

MGKF74220数控高精度立式复合磨削中心

2.沈阳黎明航空发动机(集团)有限责任公司

MGKF74100数控高精度立式复合磨削中心

3.沈阳黎明航空发动机(集团)有限责任公司

MGKF7460数控高精度立式复合磨削中心