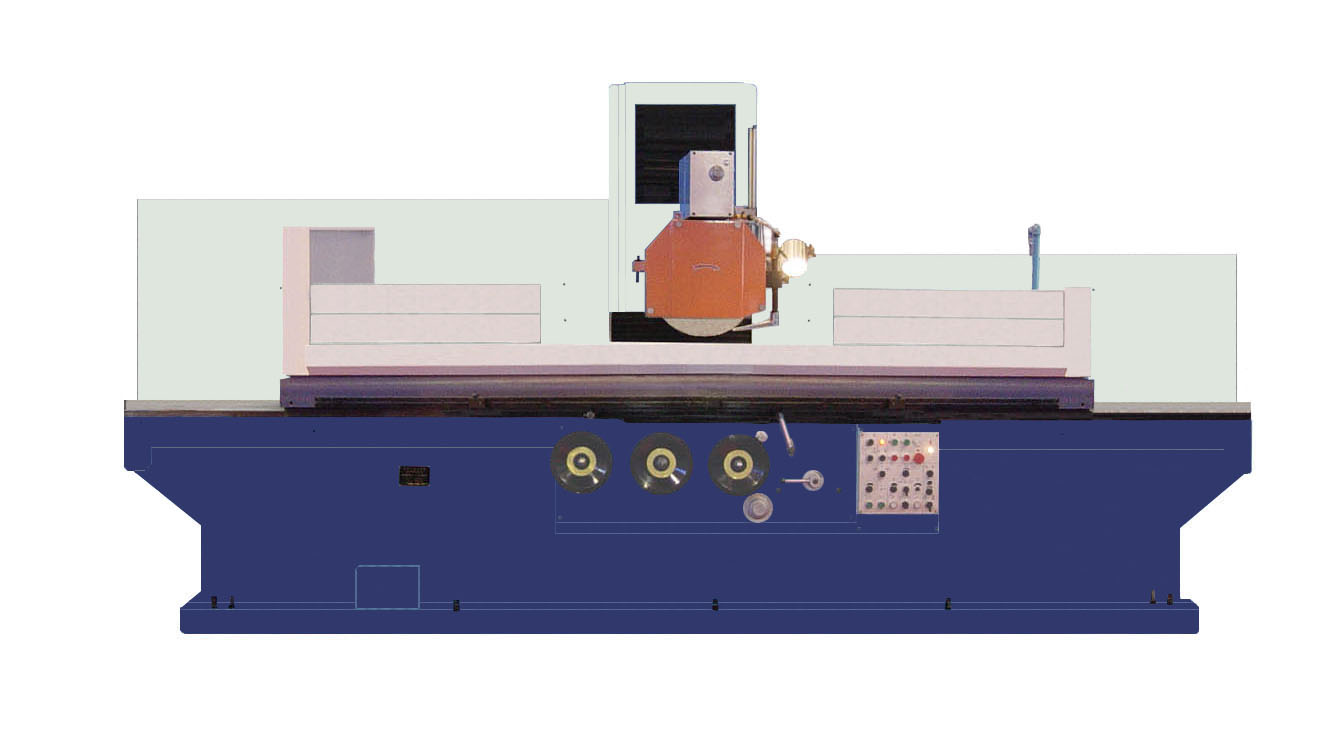

M7150 Horizontal Spindle Surface Grinder with Rectangular Table

MM7150 High- precision Horizontal Spindle Surface Grinder with Rectangular Table

1. Introduction

This machine is a large horizontal spindle rectangular table surface grinder used for grinding the surfaces of workpieces using the periphery of a grinding wheel. It can also be used for grinding the vertical surfaces and grooves of workpieces using the end face of the grinding wheel. Depending on the shape and material of the workpiece, it can be clamped on the electromagnetic worktable or secured with mechanical fixtures for grinding.

The machine adopts a column moving layout, with the bed consisting of two parts connected together by screws. The longitudinal movement is hydraulically driven with stepless speed control, while the transverse movement is electrically driven. The longitudinal guide are lubricated with a fixed-volume open hydrostatic guide system, with oil supplied to each oil chamber by two groups of multiple-gear pumps, ensuring reliable lubrication and smooth movement. The transverse guide of the carriage and the vertical guide of the column are composed of pre-tensioned embedded steel rolling guide, providing sensitive feed and easy operation. The grinding head is equipped with rapid elevation, automatic feed, and zero-position size control. The control mechanisms for the column's transverse continuous and intermittent feed adjustment, transverse reversing, buttons, and hand levers are arranged in a centralized manner for convenient operation.

The grinding head adopts hydrostatic bearings and hydrodynamic bearings (depending on user selection).

2. Technical Parameters

1. Worktable Surface Dimensions (Width x Length):

· 500x1600 mm

· 500x1000 mm

· 500x2000 mm

· 500x3000 mm

2. Electromagnetic Worktable Dimensions (Width x Length):

· 500x1000 mm (1 piece)

· 500x800 mm (2 pieces)

· 500x1000 mm (2 pieces)

· 500x1000 mm (3 pieces)

3. Maximum Grinding Height (with electromagnetic worktable removed and using the largest grinding wheel):

· 600 mm (1000, 2000)

· 550 mm (1600, 3000)

4. Grinding Wheel Dimensions (Outer Diameter x Width x Inner Diameter): 450x63x203 mm

5. Longitudinal Travel Distance of the Worktable:

· Manual: 1200 mm (1000), 1800 mm (1600), 2200 mm (2000), 3200 mm (3000)

· Hydraulic: 1000 mm (1000), 1600 mm (1600), 2000 mm (2000), 3000 mm (3000)

6. Transverse Travel Distance of the Column (Maximum): 570 mm

7. Distance from Spindle Centerline to Worktable Working Surface:

· Maximum: 825 mm (1000, 2000), 775 mm (1600, 3000)

· Minimum: 180 mm

8. Longitudinal Travel Speed of the Worktable (Hydraulic, Stepless): 2-30 m/min

9. Transverse Travel Speed of the Column (Stepless):

· Continuous Feed Speed: 0.075-1.5 m/min

· Intermittent Feed Rate: 1-30 mm/step

10.Grinding Wheel Dressing Speed (Stepless): 56-560 mm/min

11.Rapid Elevation Speed of the Grinding Head: 210 mm/min

12.Vertical Movement Distance per Revolution of the Handwheel (Worktable): 27 mm

13.Transverse Movement Distance per Revolution of the Handwheel (Column): 2 mm

14.Minimum Scale Value on the Transverse Handwheel Dial: 0.01 mm

15.Vertical Movement Distance per Revolution of the Handwheel (Grinding Head): 0.2 mm

16.Minimum Scale Value on the Vertical Handwheel Dial: 0.005 mm

17.Vertical Automatic Feed Rate of the Grinding Head (12 levels): 0.0025-0.03 mm per level, incrementing by 0.0025 mm

18.Total Power: 21.7835 kW

19.Overall Dimensions of the Machine Tool (Length x Width x Height):

3660x2449x2400 mm (1000)

4800x2449x2400 mm (1600)

5380x2449x2400 mm (2000)

7500x2449x2400 mm (3000)

20.Maximum Space Occupied by the Machine (Length x Width x Height):

5330x2599x2400 mm (1000)

5550x2599x2400 mm (1600)

5834x2599x2400 mm (2000)

8180x2599x2400 mm (3000)

21.Net Weight(Kg): 10,000, 12,000, 15,000

MT7150 Introduction

This machine is a large horizontal spindle rectangular table surface grinder with high efficiency and heavy-duty capabilities. It is suitable for grinding large molds, using the periphery of a grinding wheel to grind the surfaces of workpieces. It can also be used to grind the vertical surfaces and grooves of workpieces using the end face of the grinding wheel. Depending on the shape and material of the workpiece, either an electromagnetic worktable or mechanical fixtures can be used for workpiece clamping during grinding.

The machine adopts a column moving layout, with the bed consisting of two parts connected together by screws. The longitudinal movement is hydraulically driven with stepless speed control, while the transverse movement is electrically driven. The longitudinal guide are lubricated with a fixed-volume open hydrostatic guide system, with oil supplied to each oil chamber by multiple-gear pumps, ensuring reliable lubrication and smooth movement. The transverse guide of the carriage and the vertical guide of the column are composed of pre-tensioned embedded steel guide, providing sensitive feed and easy operation. The grinding head is equipped with rapid elevation, automatic feed, and zero-position size control. The control mechanisms for the column's transverse continuous and intermittent feed adjustment, transverse reversing, buttons, and hand levers are arranged in a centralized manner for convenient operation.

The main spindle bearings of the grinding head in this machine are rolling bearings. If users have special requirements, hydrostatic bearings can also be installed, but this needs to be specified in the purchase contract.

1. Parameters

1. Worktable Surface Dimensions (Wx H): 500x2000mm

2. Electromagnetic Worktable Dimensions (Wx L): 500x1000mm (two pieces)

3. Maximum Grinding Height (when removing electromagnetic worktable and using the largest grinding wheel): 600mm

4. Grinding Wheel Dimensions (Outer Diameter x Width x Inner Diameter): 450x63x203mm

Minimum Outer Diameter of Grinding Wheel: 320mm

5. Width of T-slot on the Worktable: 18mm

6. Number of T-slots on the Worktable: 3

7. Longitudinal Travel Distance of the Worktable:

· Manual: 2200mm

· Hydraulic: 2000mm

8. Transverse Travel Distance of the Column (Maximum): 570mm

9. Distance from the Centerline of the Spindle to the Worktable Surface:

· Maximum: 825mm

· Minimum: 180mm

10.Longitudinal Travel Speed of the Worktable (Hydraulic, Stepless): 2-30m/min

11.Transverse Travel Speed of the Column (Stepless):

· Continuous Feed Speed: 0.075-1.5m/min

· Intermittent Feed Rate: 1-30mm/stroke

12.Grinding Wheel Dresser Speed (Stepless): 560-56mm/min

13.Rapid Elevation Speed of the Grinding Head: 210mm/min

14.Longitudinal Movement Distance per Revolution of the Handwheel: 27mm

15.Transverse Movement Distance per Revolution of the Handwheel: 2mm

16.Minimum Scale Value on the Transverse Handwheel Dial: 0.01mm

17.Vertical Movement Distance per Revolution of the Handwheel: 0.2mm

18.Minimum Scale Value on the Vertical Feed Handwheel Dial: 0.005mm

19.Automatic Vertical Feed Rate of the Grinding Head (12 levels): 0.0025-0.03mm per level (increase per step 0.0025mm)

20.Motor:

· Grinding Wheel Rotation Motor (Built-in): 15kw, 1460rpm

· Transverse Travel Motor for the Column: 0.355kw, 75-1500rpm

· Rapid Elevation Motor for the Grinding Head: 0.55kw, 1400rpm

· Grinding Wheel Dresser Motor: 0.0135kw, 200rpm

· Hydraulic Pump Motor: 4kw, 2900rpm

· Guide Rail Lubrication Pump Motor: 0.09kw, 360-3600rpm

· Cooling Oil Tank Fan Motor: 0.55kw, 1390rpm

· Coolant Pump Motor: 0.12kw, 2700rpm

· Exchange Oil Pump Motor: 0.55kw, 1400rpm Total: 21.2285kw

21.Flow Rates of Various Pumps:

· Coolant Pump Flow Rate: 50 liters/minute

· Hydraulic Pump Flow Rate (Screw Pump): 2900rpm, 90 liters/minute

· Exchange Oil Pump Flow Rate: 18 liters/minute

· Guide Rail Lubrication Pump Flow Rate: 0.95-9.5m3/minute

22.Electromagnetic Worktable Suction Force: 8kg/cm2

23.Overall Dimensions of the Machine Tool (Length x Width x Height): 5380x2449x2400mm

24.Machine size (Lx Wx H): 5834x2449x2400mm

25.Net Weight: 12000kg

MM7150 High- precision Horizontal Spindle Surface Grinder with Rectangular Table

1. Introduction

This machine is a large precision horizontal spindle rectangular table surface grinder. It is used to grind the surfaces of workpieces using the periphery of a grinding wheel. It can also be used to grind the vertical surfaces and grooves of workpieces using the end face of the grinding wheel. Depending on the shape and material of the workpiece, either an electromagnetic worktable or mechanical fixtures can be used for workpiece clamping during grinding.

The machine adopts a column moving layout, with the bed consisting of two parts connected together by screws. The longitudinal movement is hydraulically driven with stepless speed control, while the transverse movement is electrically driven. The longitudinal guide are lubricated with a fixed-volume open hydrostatic guide system, with oil supplied to each oil chamber by two sets of multiple-gear pumps, ensuring reliable lubrication and smooth movement. The transverse guide of the carriage and the vertical guide of the column are composed of pre-tensioned embedded steel rolling guide, providing sensitive feed and easy operation. The grinding head is equipped with rapid elevation, automatic feed, and zero-position size control. The control mechanisms for the column's transverse continuous and intermittent feed adjustment, transverse reversing, buttons, and hand levers are arranged in a centralized manner for convenient operation. The spindle is in a hydrostatic form.

2. Parameters

1. Worktable surface dimensions (Width x Length): 500x1000mm

2. Electromagnetic worktable dimensions (Width x Length): 500x1000mm (1 piece)

3. Maximum grinding height (with electromagnetic worktable removed and using the largest grinding wheel): 600mm

4. Grinding wheel dimensions (Outer Diameter x Width x Inner Diameter): 450x63x203mm

5. Longitudinal movement distance of the worktable:

· Manual: 1200mm (1000)

· Hydraulic: 1000mm (1000)

6. Transverse travel of the column (maximum): 570mm

7. Distance from the spindle centerline to the worktable working surface:

· Maximum: 825mm

· Minimum: 180mm

8. Longitudinal movement speed of the worktable (hydraulic stepless speed control): 2-30m/min

9. Transverse movement speed of the column (stepless speed control):

· Continuous feed speed: 0.075-1.5m/min

· Intermittent feed rate: 1-30mm/stroke

10.Grinding wheel dresser speed (stepless speed control): 56-560mm/min

11.Rapid elevation speed of the grinding head: 210mm/min

12.Longitudinal movement amount per revolution of the handwheel for the worktable: 27mm

13.Transverse movement per revolution of the handwheel for the column: 2mm

14.Minimum scale value on the handwheel for transverse movement: 0.01mm

15.Vertical movement per revolution of the handwheel for the grinding head: 0.2mm

16.Minimum scale value on the handwheel for vertical feed: 0.005mm

17.Automatic vertical feed of the grinding head (12 levels): 0.0025-0.03mm per level, increasing by 0.0025mm

18.Motor power: 21.7835kW

19.Machine dimensions (Length x Width x Height): 3660x2449x2400mm (1000)

20.Machine size (Length x Width x Height): 5330x2599x2400mm (1000)

21.Net weight : 10000kg

Introduction of MT7150

The MT7150 machine is a large horizontal spindle rectangular table surface grinding machine. It is characterized by high efficiency and heavy load capacity, suitable for grinding large molds and grinding the flat surfaces of workpieces with the periphery of a grinding wheel. It can also be used to grind the vertical surfaces and chamfers of workpieces with the end face of a grinding wheel. The workpiece clamping method varies depending on the shape and material of the workpiece, and can be achieved using an electromagnetic worktable or mechanical fixtures securely fastened to the worktable for grinding.

This machine adopts a column movement layout, with the bed divided into two parts connected by screws. The machine movement is achieved through hydraulic infinitely variable speed control in the longitudinal direction and electrical drive in the transverse direction. The longitudinal guide lubrication adopts a constant-volume open static pressure guide, with multiple gear pumps supplying oil to each oil chamber, ensuring reliable lubrication and easy movement. Both the transverse guide of the drag plate and the vertical guide of the column are composed of pre-tensioned steel guide, providing sensitive feeding and easy operation. The grinding head features rapid vertical movement, automatic feed, and zero position size control. The adjustment of the transverse continuous and intermittent feed rates of the column, as well as the transverse reversing mechanism, buttons, handles, and other control mechanisms, are arranged centrally for convenient operation.

The main spindle bearings of this machine grinding head are equipped with rolling bearings.

Technical Parameters:

1. Worktable surface dimensions (W x H): 500x1000mm

2. Electromagnetic table dimensions (W x L): 500x1000mm

3. Maximum grinding height (with electromagnetic table removed and using the largest grinding wheel): 600mm

4. Grind wheel dimensions (outer diameter x width x inner diameter): 450x63x203mm

5. Longitudinal movement distance of the worktable:

· Manual: 2200mm

· Hydraulic: 2000mm

6. Transverse travel of the column (maximum): 570mm

7. Distance from the centerline of the spindle to the surface of the worktable:

· Maximum: 825mm

· Minimum: 180mm

8. Longitudinal movement speed of the worktable (hydraulic stepless speed speed): 2-30m/min

9. Transverse movement speed of the column (stepless speed):

· Continuous feed speed: 0.075-1.5m/min

· Intermittent feed rate: 1-30mm/step

10.Grind wheel dressing speed (stepless speed): 560-56mm/min

11.Rapid up and down speed of the grinding head: 210mm/min

12.Longitudinal movement distance per revolution of the handwheel for the worktable: 27mm

13.Transverse movement distance per revolution of the handwheel for the column: 2mm

14.Minimum scale value of the transverse handwheel dial: 0.01mm

15.Vertical movement distance per revolution of the handwheel for the grinding head: 0.2mm

16.Minimum scale value of the vertical feed handwheel: 0.005mm

17.Vertical automatic feed of the grinding head (12 levels):

· 0.0025-0.03mm

· Per step increase 0.0025mm

18.Motors:

a) Grind wheel rotation motor (built-in): Power 15 kW, Speed 1460 rpm

b) Transverse movement motor for the column: Power 0.355 kW, Speed 75-1500 rpm

c) Rapid up and down motor for the grinding head: Power 0.55 kW, Speed 1400 rpm

d) Grind wheel dressing motor: Power 0.0135 kW, Speed 200 rpm

e) Hydraulic pump motor: Power 4 kW, Speed 2900 rpm

f) Guide lubrication pump motor: Power 0.09 kW, Speed 360-3600 rpm

g) Oil tank air cooling motor: Power 0.55 kW, Speed 1390 rpm

h) Cooling pump motor: Power 0.12 kW, Speed 2700 rpm

i) Exchange oil pump motor: Power 0.55 kW, Speed 1400 rpm Total: 21.2285 kW

19.Flow rates of each pump:

a) Cooling pump flow rate: 50 liters/min

b) Hydraulic pump flow rate (screw pump): 2900 rpm, 90 L/min

c) Exchange oil pump flow rate: 18 L/min

d) Guide lubrication pump flow rate: 0.95-9.5m3/min

20.Electromagnetic table suction force: 8 kg/cm2

21.Machine dimensions (L x W x H): 5380x2449x2400mm

22.Maximum occupied space of the machine tool (L x W x H): 5834x2449x2400mm

23.Net weight: 12000 kg