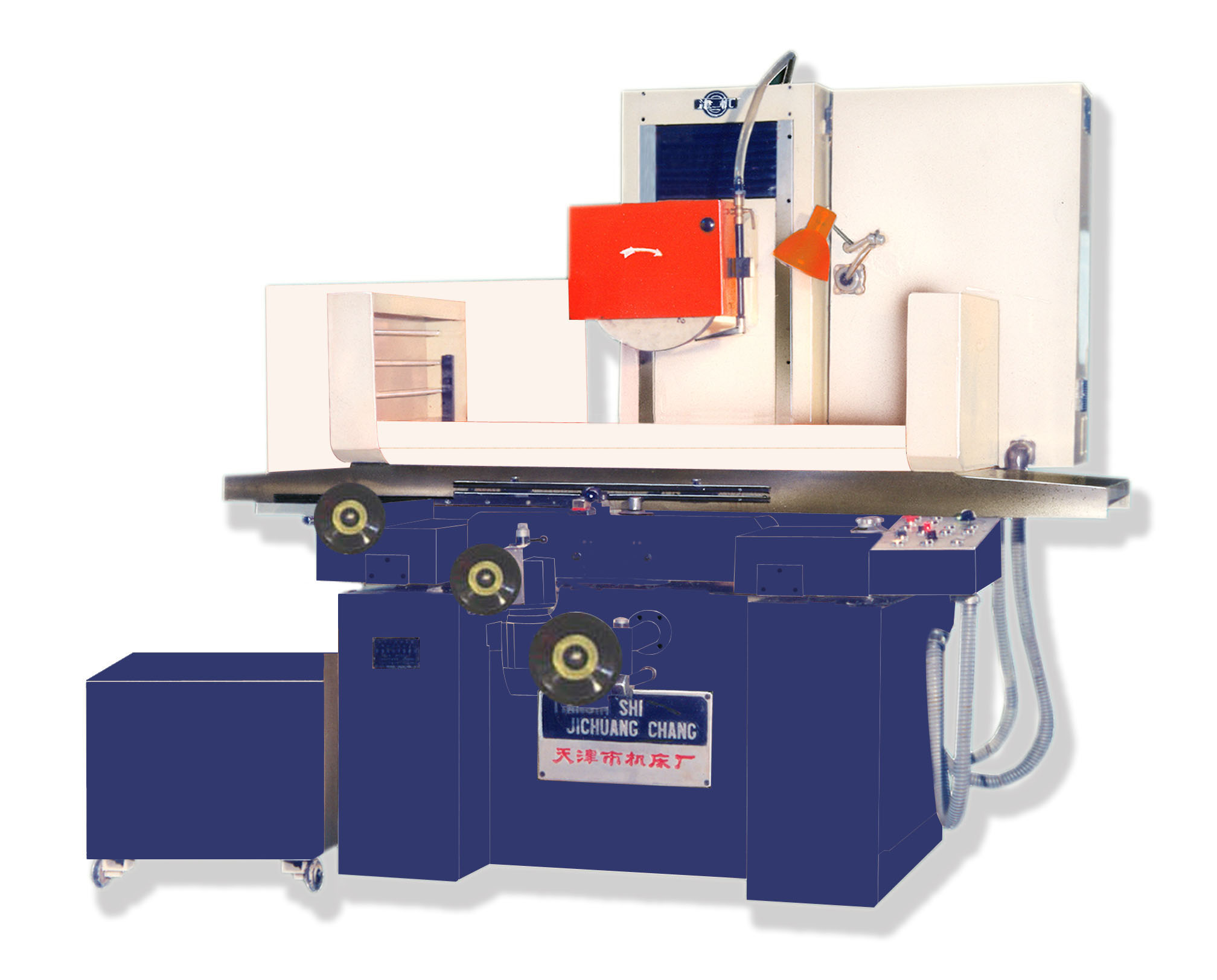

M7140 Horizontal Spindle Surface Grinder with Rectangular Table

Introduction of the M7140A/1M

1. Machine characteristics

M7140A/1M is a horizontal spindle rectangular table surface grinding machine that adopts a cross-shaped worktable layout with the drag plate for transverse motion. The worktable moves longitudinally on the drag plate, while the grinding head only performs vertical up and down movement. The bed is a T-shaped box-type structure, and the column is a double-wall design. The machine has a compact structure, good system rigidity, stable accuracy, convenient operation, and an aesthetic appearance.

The longitudinal, transverse, and vertical motion guideways of the machine tool are all equipped with steel-inlaid hardened rolling guideways, which provide simple lubrication, smooth motion, and long service life.

The wheelhead adopts a sleeve-type full rolling bearing, ensuring high precision, reliable lubrication, and convenient maintenance. The spindle is directly driven by an installed motor, providing high cutting power. The wide grinding wheel allows for rough grinding, ensuring high productivity, as well as precise grinding to achieve high machining accuracy. The grinding head has hydraulic automatic vertical feed, zero- position control, and quick lifting device, enabling sensitive and accurate feeding. It has a certain degree of automation and easy operation.

2. Parameters

1) Magnetic worktable surface dimensions (W x L): 400 x 1000 mm

2) Maximum height of the workpiece for grinding: 430 mm.

3) Worktable:

a. Maximum longitudinal travel

i. Manual: 1150 mm

ii. Hydraulic: 1100 mm.

b. Longitudinal travel speed (hydraulic, stepless): 3-25 m/min.

c. Worktable movement per revolution of the longitudinal handwheel: 75 mm.

4) Drag plate:

a. Maximum transverse travel: 450 mm.

b. Transverse travel speed:

i. AC drive: 1.4 m/min.

ii. DC drive: 0.064-0.64 m/min.

c. Intermittent feed in the transverse direction:

i. AC drive: 2-20 mm/stroke.

ii. DC drive: 1-10 mm/stroke.

d. Transverse feed per revolution of the handwheel: 5 mm.

e. Minimum scale value of the transverse handwheel dial: 0.005 mm.

f. Transverse micro-feed: 0.002 mm.

5) Grinding head:

a) Distance from the spindle centerline to the worktable surface: Maximum/Minimum - 605 mm/110 mm.

b) Maximum vertical travel: 495 mm.

c) Rapid lifting speed: 250 mm/min.

d) Vertical feed per revolution of the handwheel: 0.5 mm.

e) Minimum scale value of the vertical handwheel dial: 0.005 mm.

f) Manual vertical micro-feed: 0.0025 mm.

g) Automatic vertical feed (hydraulic, 6 levels): 0.0025, 0.005, 0.0075, 0.01, 0.015, 0.02 mm.

h) Spindle motor power/speed: 5.5 kW/1440 rpm.

i) Grinding wheel dimensions (outer diameter x width x inner diameter): φ350 x 40 x φ127 mm.

j) Hydraulic correction speed for the grinding wheel: 0.02-0.7 m/min.

6) Flow rate and pressure of the hydraulic oil pump: 25 L/min, 25 kg/cm².

7) Motor power and speed:

i. Grinding head motor: 5.5 kW, 1440 rpm.

ii.Hydraulic oil pump motor: 1.1 kW, 2800 rpm.

iii.Transverse feed motor (AC drive): 0.12 kW, 1400 rpm.

iv. Transverse feed motor (DC drive): 0.185 kW, 1500 rpm.

v. Rapid lifting motor of the wheel head: 0.25 kW, 1400 rpm.

vi. Cooling water pump motor: 0.09 kW, 2800 rpm.

vii.Total power of the machine: 7.125 kW.

8) Overall dimensions of the machine (Lx Wx H): 2970 x 1808 x 2000 mm.

9) Machine weight: 4400 kg.

M7140A Horizontal Spindle Surface Grinder with Rectangular table

1. Machine characteristics

M7140A is a horizontal spindle reciprocating table surface grinding machine, which belongs to the category of short and wide general-purpose surface grinders. It is primarily used for grinding the flat surfaces of workpieces using the periphery of a grinding wheel. Additionally, it can also be used to grind the vertical surfaces or slots of workpieces using the end face of the grinding wheel. Depending on the material and shape of the workpiece, it can be either magnetically attracted to the electromagnetic worktable or clamped in mechanical fixtures for processing. The machine tool has high production efficiency and is suitable for machining precision parts, especially short and wide molds and combination fixtures. It can be widely used in metalworking and tool workshops in industries such as machinery, tools, molds, automotive, tractors, and appliances.

The machine tool adopts a cross-shaped worktable layout with the drag plate for transverse motion. The worktable moves longitudinally on the drag plate, while the grinding head only performs vertical up and down movement. The bed structure is in the form of a T-shaped box, and the column is designed as a double-wall structure. The machine tool has a compact structure, good system rigidity, stable accuracy, convenient operation, and an aesthetically pleasing appearance. The longitudinal, transverse, and vertical motion guideways of the machine tool all use steel-inlaid hardened rolling guideways, which provide simple lubrication, smooth motion, and long service life.

2. Technical Specifications

1) Magnetic worktable surface dimensions (W x L): 400 x 630(800) mm.

2) Maximum height of the workpiece for grinding: 430 mm.

3) Worktable:

Maximum longitudinal travel:

· Manual: 750(920) mm.

· Hydraulic: 700(870) mm.

· Longitudinal travel speed (hydraulic, stepless): 3-25 m/min.

· Worktable movement per revolution of the longitudinal handwheel: 75 mm.

4) Drag plate:

Maximum transverse travel: 450 mm.

Transverse travel speed:

· AC drive: 1.4 m/min.

· DC drive: 0.064-0.64 m/min.

Intermittent feed in the transverse direction:

· AC drive: 2-20 mm/stroke.

· DC drive: 1-10 mm/stroke.

Transverse feed per revolution of the handwheel: 5 mm.

Minimum scale value of the transverse handwheel dial: 0.005 mm.

Transverse micro-feed: 0.002 mm.

5) Grinding head:

Distance from the spindle centerline to the worktable surface: Maximum/Minimum - 605 mm/110 mm.

Maximum vertical travel: 495 mm.

Rapid lifting speed: 250 mm/min.

Vertical feed per revolution of the handwheel: 0.5 mm.

Minimum scale value of the vertical handwheel dial: 0.005 mm.

Manual vertical micro-feed: 0.0025 mm.

Automatic vertical feed (hydraulic, 6 levels): 0.0025, 0.005, 0.0075, 0.01, 0.015, 0.02 mm.

Spindle motor power/speed: 5.5 kW/1440 rpm.

Grinding wheel dimensions (outer diameter x width x inner diameter): φ350 x 40 x φ127 mm.

6) Flow rate and pressure of the hydraulic oil pump: 25 L/min, 25 kg/cm².

7) Motor power and speed:

Grinding head motor: 5.5 kW, 1440 rpm.

Hydraulic oil pump motor: 1.1 kW, 2800 rpm.

Transverse feed motor (AC drive): 0.12 kW, 1400 rpm.

Transverse feed motor (DC drive): 0.185 kW, 1500 rpm.

Rapid lifting motor of the wheel head: 0.25 kW, 1400 rpm.

Cooling water pump motor: 0.09 kW, 2800 rpm.

Total power of the machine tool: 7.125 kW.

8) Overall dimensions of the machine tool (Lx Wx H): 2200 x 1808 x 2000 mm, (2460 x 1808 x 2000) mm.

9) Machine weight: 4000(4200) kg.

MM7140 Technical Documentation

1. Machine characteristics

This machine is used for grinding the horizontal surface of workpieces using the periphery of a grinding wheel. It can also be used for grinding the vertical faces and grooves of workpieces using the end face of the grinding wheel. The machine structure adopts a cross-shaped layout with a movable carriage worktable. The longitudinal, transverse, and vertical guide all use embedded steel hardened rolling guide, which provide simple lubrication, smooth movement, and long service life.

The longitudinal movement of the worktable is hydraulically driven with stepless speed control, while the transverse movement of the carriage is electrically driven, allowing for rapid movement and intermittent feed functions. The grinding head utilizes a sleeve-type fully rolling bearing and features vertical automatic feed, zero position dimension control, and a rapid elevation device. It is suitable for grinding precision parts.

2. Parameters

1) Worktable Surface Dimensions (Width x Length): 400x630 (800) mm

2) Maximum Height of Grinding Workpiece: 430 mm

3) Worktable:

Electromagnetic Worktable Dimensions (Width x Length): 400x630 (800) mm

Maximum Travel Distance in the Vertical Direction:

Manual: 750 (920) mm

Hydraulic: 700 (870) mm

Vertical Travel Speed (Hydraulic, Stepless): 3~25 m/min

Vertical Movement Distance per Revolution of the Handwheel: 75 mm

4) Carriage:

a) Maximum Travel Distance in the Transverse Direction: 450 mm

b) Transverse Movement Speed:

1. AC Motor Drive: 1.4 m/min

2. DC Motor Drive: 0.064~0.64 m/min

c) Transverse Intermittent Feed Rate:

1. AC Motor Drive: 2-20 mm/stroke

2. DC Motor Drive: 1~10 mm/stroke

d) Transverse Movement Distance per Revolution of the Handwheel: 5 mm

e) Minimum Scale Value on the Transverse Feed Handwheel: 0.005 mm

f) Transverse Manual Microfeed Distance: 0.002 mm

5) Grinding Head:

a) Distance from Spindle Centerline to Worktable Surface: Max/Min 605/110 mm

b) Maximum Vertical Travel Distance: 495 mm

c) Rapid Elevation Speed: 250 mm/min

d) Vertical Movement Distance per Revolution of the Feed Handwheel: 0.5 mm

e) Minimum Scale Value on the Vertical Feed Handwheel: 0.005 mm

f) Manual Vertical Microfeed Distance: 0.0025 mm

g) Automatic Vertical Feed Rate (Hydraulic, 6 levels): 0.0025, 0.005, 0.0075, 0.01, 0.015, 0.02 mm

h) Spindle Speed: 1440 r/min

i) Hydraulic Wheel Dressing Speed: 0.02~0.7 m/min

j) Grinding Wheel Dimensions (Outer Diameter x Width x Inner Diameter): φ350x40xφ127 mm

6) Flow Rate and Pressure of Hydraulic Oil Pump: 25 L/min, 25 Kg/cm2

7) Electric Power and Speed:

1. Grinding Head Motor: 5.5 Kw, 1440 r/min

2. Hydraulic Oil Pump Motor: 1.1 Kw, 2800 r/min

3. Transverse Feed Motor for Carriage:

l AC Motor Drive: 0.12 Kw, 1400 r/min

l DC Motor Drive: 0.185 Kw, 1500 r/min

4. Rapid Elevation Motor for Grinding Head: 0.25 Kw, 1400 r/min

5. Cooling Water Pump Motor: 0.09 Kw, 2800 r/min

6. Power of the Machine Tool: 7.125 Kw

8) Overall Dimensions of the Machine (LxWxH): 2200x1808x2000 mm (2460x1808x2000 mm)

9) Machine Weight: 4000 (4200) Kg