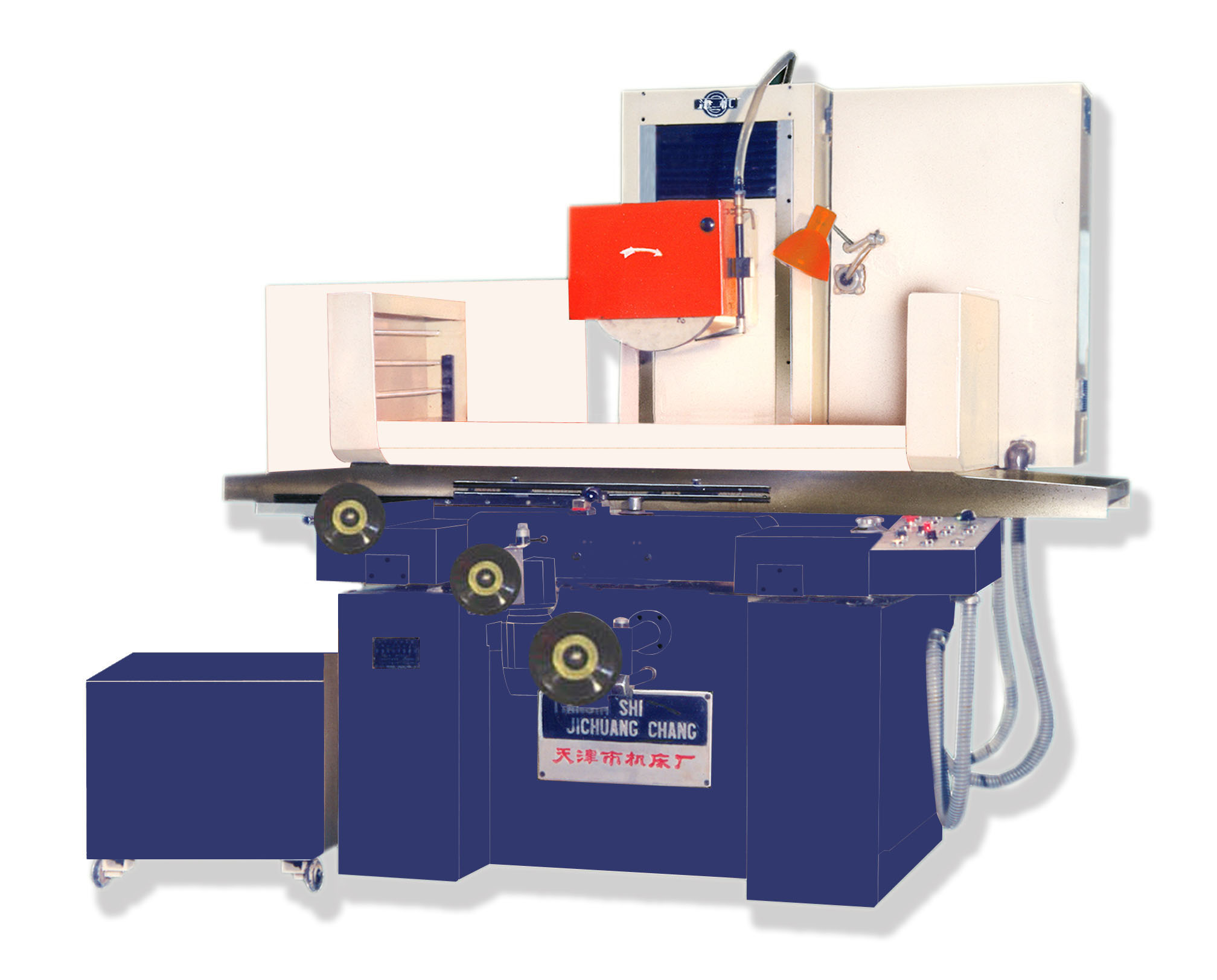

M7125Horizontal Spindle Surface Grinder with Rectangular Table

MG7125 Hight Precision Horizontal Spindle Surface Grinder with Rectangular Table

1.Machine characteristics

The machine tool structure adopts a cross-shaped worktable layout with a drag plate for movement. The longitudinal, transverse, and vertical guideways all use steel-inlaid hardened rolling guideways, which provide simple lubrication, smooth motion, and long service life.

This machine tool is used to grind the horizontal surfaces of workpieces using the periphery of a grinding wheel. It can also be used to grind the vertical faces and slots of workpieces using the end face of the grinding wheel.

The longitudinal movement of the worktable is hydraulically driven with stepless speed regulation, while the drag plate's transverse movement is electrically driven. The DC motor with controllable silicon provides stepless speed regulation with a wide range, meeting the requirements for rapid movement, intermittent feed, and low-speed dressing of the grinding wheel. The grinding head adopts liquid static pressure bearings, which enable vertical automatic feeding, zero-position control, and quick lifting device. It is suitable for grinding precision parts.

2. Parameters

1) Worktable surface dimensions (Lx W): 630 x 250 mm.

2) Electromagnetic worktable dimensions (L x W x H): 600 x 250 x 100 mm.

3) Grind workpiece size (L x W x H): 630 x 250 x 375 mm.

4) Distance from the spindle centerline to the worktable surface: Max/Min - 550/110 mm.

5) Spindle speed: 1450 rpm

6) Vertical travel of the wheel head: 440 mm.

7) Rapid lifting speed of the wheel head: 200 mm/min

8) Longitudinal travel of the worktable:

· Manual: 750 mm.

· Power: 700 mm.

9) Longitudinal travel speed (hydraulic, stepless): 1-22m/min

10) Transverse travel of the drag plate: 300 mm.

11) Transverse travel speed of the drag plate: 15-1500 mm/min.

12) Wheel head movement per revolution of the lifting handwheel: 0.20 mm.

13) Minimum scale value of the lifting handwheel: 0.001 mm.

14) Manual vertical micro-feed of the wheel head: 0.001 mm.

15) Automatic vertical feed of the wheel head (hydraulic, 6 levels): 0.001, 0.002, 0.004, 0.006, 0.008, 0.010 mm.

16) Worktable movement per revolution of the longitudinal handwheel: 75 mm.

17) Drag plate movement per revolution of the transverse handwheel: 5 mm.

18) Minimum scale value of the transverse handwheel: 0.05 mm.

19) Transverse micro-feed of the drag plate: 0.002 mm.

20) Transverse intermittent feed of the drag plate (electrical, stepless): 0.10-5 mm/time

21) Grinding wheel dimensions (Outer diameter x width x Inner diameter): φ350 x 32 x φ127 mm.

22) Motor power and speed:

Wheel head motor: 4kw, 1450 rpm

Hydraulic oil pump motor: 1.1 kw, 2810 rpm

Drag plate DC motor: 0.16 kw, 220 v.

Rapid lifting motor of the grinding head: 0.25 kw, 1400 rpm

Hydrostatic bearing oil pump motor: 0.55 kw, 1400 rpm

Cooling water pump and dust collector motor: 1.1 kw, 2810 rpm

Air-cooled radiator motor: 0.09 kw, 1390 rpm

23) Flow rate and pressure of the hydraulic oil pump: 25 L/min, 25 kg/cm2

24) Flow rate and pressure of the static pressure bearing oil pump: 6L/min, 25kg/cm2.

25) Machine tool dimensions (L x W x H): 2590 x 1851 x 1900 mm.

26) Machine weight: 3000 kg.

MM7125 Technical Documents

1.Machine characteristics

This machine is used to grind the horizontal surfaces of workpieces using the periphery of a grinding wheel. It can also be used to grind the vertical faces and slots of workpieces using the end face of the grinding wheel.

The machine structure adopts a cross-shaped worktable layout with a drag plate for movement. The longitudinal, transverse, and vertical guideways all use steel-inlaid hardened rolling guideways, which provide simple lubrication, smooth motion, and long service life, making maintenance convenient.

The longitudinal movement of the worktable is hydraulically driven with stepless speed regulation, while the transverse movement of the drag plate is electrically driven, providing functions for rapid movement and intermittent feed. The grinding head adopts short three-piece tile oil film bearings, which enable vertical automatic feeding, zero- position control, and quick lifting device. It is suitable for grinding precision parts.

The safety and protective technical requirements of the equipment should comply with the national standards of the People's Republic of China. The protective devices are safe and reliable, and they meet the general technical requirements for protection of metal cutting machine tools specified in GB15760-1995.

2. Technical Specifications

1) Worktable dimensions (Lx W): 630(800) x 250 mm.

2) Electromagnetic worktable dimensions (Lx W x H): 600(800) x 250 x 100(110) mm.

3) Workpiece size (Lx W x H): 630(800) x 250 x 400 mm.

4) Distance from the spindle centerline to the worktable surface: Min 100 mm, Max 550 mm.

5) Spindle speed: 1400/2800 rpm

6) Maximum vertical movement of the grinding head: 450 mm.

7) Rapid lifting speed of the grinding head: 250 mm/min.

8) Maximum longitudinal movement of the worktable:

· Manual: 750(920) mm.

· Power: 700(870) mm.

9) Longitudinal movement speed of the worktable (hydraulic, stepless): 1-25 m/min.

10) Maximum transverse movement of the drag plate: 300 mm.

11) Transverse movement speed of the drag plate (continuous): 1.4 m/min.

12) Grinding head movement per revolution of the lifting handwheel: 0.5 mm.

13) Minimum scale value of the lifting handwheel dial: 0.005 mm.

14) Manual vertical micro-feed of the grinding head: 0.0025 mm.

15) Automatic vertical feed of the grinding head (hydraulic, 6 levels): 0.0025, 0.005, 0.0075, 0.01, 0.015, 0.02 mm.

16) Worktable movement per revolution of the longitudinal handwheel: 75 mm.

17) Drag plate movement per revolution of the transverse handwheel: 5 mm.

18) Minimum scale value of the transverse handwheel dial: 0.05 mm.

19) Transverse micro-feed of the drag plate: 0.002 mm.

20) Transverse intermittent feed of the drag plate: 1-14 mm/stroke.

21) Grinding wheel dimensions (outer diameter x inner diameter x width): 300 x 75 x 40 mm.

22) Motor power and speed:

Grinding head motor: 4.5/5.5 kW, 1400/2800 r/min.

Hydraulic oil pump motor: 1.1 kW, 2810 r/min.

Drag plate feeding motor: 0.185 kW, 1500 r/min.

Grinding head rapid lifting motor: 0.25 kW, 1400 r/min.

Grinding head lubrication oil pump motor: 0.08 kW, 1400 r/min.

Cooling water pump motor: 0.09 kW, 2800 r/min.

23) Flow rate and pressure of the hydraulic oil pump: 25 L/min, 2.5 MPa.

24) Flow rate of the cooling water pump: 25 L/min.

25) Overall dimensions of the machine tool (L x W x H): 2300(2500) x 1500 x 1900 mm.

26) Machine weight: 2800(3000) kg.

27) Packaging dimensions of the machine (L x W x H): 2700 x 1920 x 2200 mm, 2850 x 1920 x 2400 mm.

28) Net weight of the machine: 2800(3000) kg.

29) Gross weight of the machine: 3400(3700) kg.