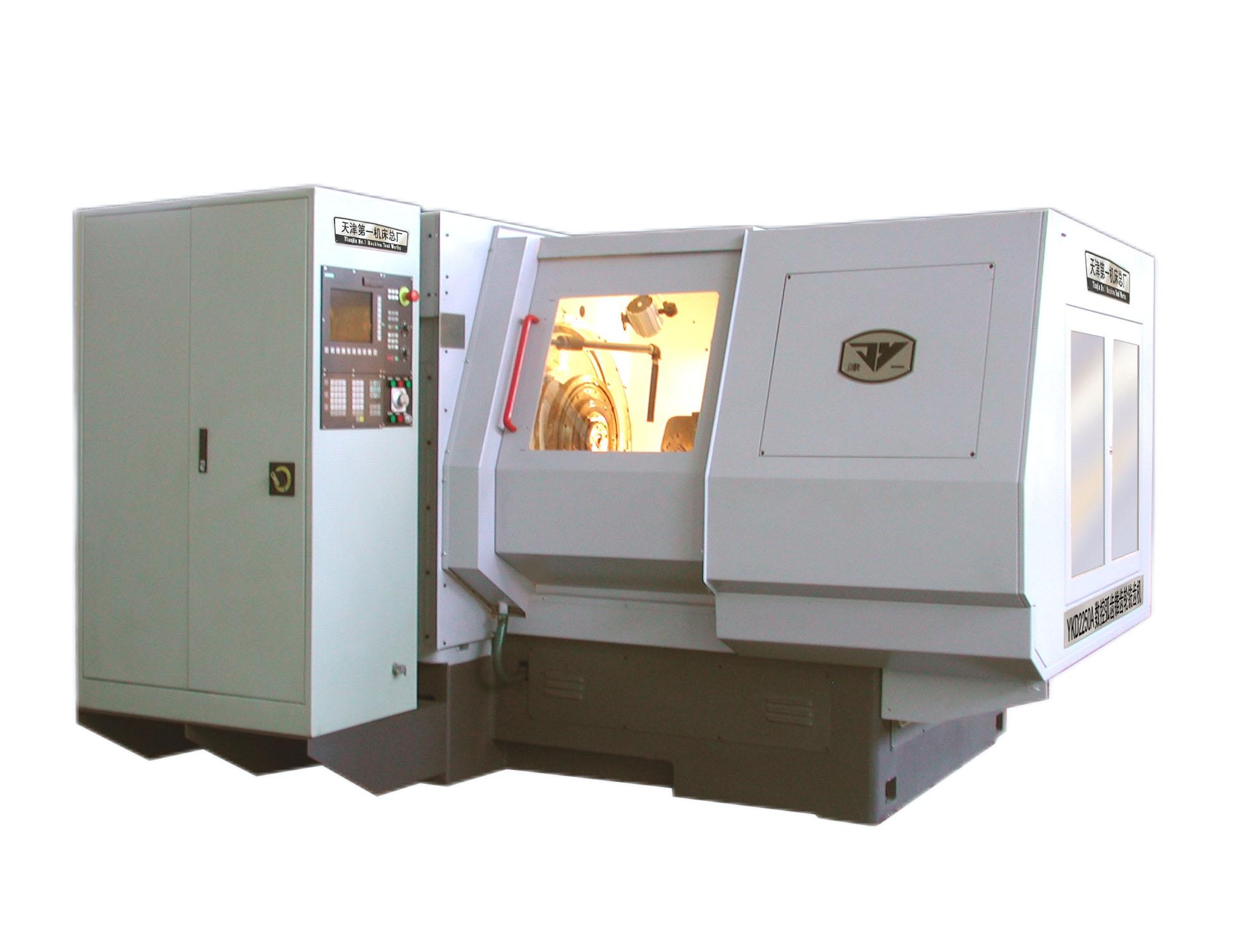

YKD2250A CNC Spiral Bevel Gear Generator

YKD2250A CNC SPIRAL BEVEL GEAR GENERATOR

1. Main Usage of Machine

On this machine, many cutting methods can be adopted for roughing and finishing Spiral Bevel, Zero Bevel and Hypoid Gears up to 500mm in diameter and 12 mm in module. The machine is most suitutable for batch production or mass production of driving pinions of gear pairs used in cars, light and medium-sized trucks and construction machineries.

2. Main Features and Structural Characteristics of Machine

1. The machine is designed to operate as a three axes CNC control Spiral Bevel Gear Generator, i.e. cradle oscillation (X axis), work spindle rotation (Y axis) and sliding base movement (Z axis). Each of three axes will be separately or simultaneously controlled. The rotation of cutter spindle (S axis) is controlled by an AC frequency variable motor for its stepless control.

2. A high precision dual-leads worm gear set is used for cradle drive and work spindle drive respectively, and many measures are adopted for improving the structural and driving rigidity of machine, so as to ensure the machining accuracy, productivity and operating lifes.

3. A cutter tilt mechanism with maximum tilt angle 30°is designed for the cutter spindle for cutting the pinions to mesh with non-generated gears (minimum gear ratio 2.5:1) and getting better tooth bearing correction.

4. There are no any change gears on the machine for minimizing the setting time of machine.

5. The feeds of machine are controlled by CNC programme, so as to simplify the operation and increase the cutting efficiency.

6. CNC control system, main electrical and hydraulic components, critical bearings and sealings are fine quality imports, which guarantee the machine reliability.

7. The machine is equipped with an independent sealed electrical cabinet, which is with air conditioner or thermo exchanger.

8. Safety guards and auto-chip conveyor can be provided on the machine.

3. Main Technical Specifications of Machine

一.被加工工件尺寸 | 1. Dimensions of work to be cut | |

最大外锥距(30°螺旋角与12″刀盘) Max. outer cone distance(Spiralangle 30°and 12 ″cutter) | mm | 250 |

最大传动比 Max. ratio | 10:1 | |

最大节圆直径(30°螺旋角) Max. diameter (Spiral angle 30°) | ||

传动比10:1 Ratio 10:1 | mm | 500 |

传动比2:1 Ratio 2:1 | mm | 450 |

传动比1:1 Ratio 1:1 | mm | 350 |

最大加工模数 Max. module | mm | 12 |

最大切齿深度 Max. cutting depth | mm | 25 |

最大齿圈宽度 Max.face width | mm | 70 |

最大径向刀位 Max. radial | mm | 222.25 |

二.工件主轴 | 2. Work spindle | |

主轴锥孔大端直径 Diameter of taper hole at large end | mm | 100 |

锥 度 Taper | 1:20 | |

主轴通孔直径 Diameter of through hole | mm | 78 |

主轴端部直径 Face diameter | mm | 145 |

三.刀盘直径 | 3. Cutter diameter 6″,7.5 ″,9″,12″ | |

四.工件箱调整量 | 4. Workhead settings | |

主轴最大垂直位移 Offset of work spindle | mm | ±70 |

主轴端面至机床中心距离 Machine centre to nose of spindle | mm | 100~360 |

五.刀盘调整量 | 5.Cutter settings | |

刀盘转速(无级) Speed (stepless) | rpm | 20~140 |

进给速度(秒/每齿) Feeds | sec/tooth | 20~80 |

最大刀倾角 Max. tilt angle | 30° | |

六.其它 | 6.Miscellaneous | |

主电机功率 Power of main motor | kw | 5.5 |

机床电气总功率 Total power of motors | kw | 34 |

机床外形尺寸(长×宽×高) Overall dimensions | mm | 2507×1875×1846 |

机床净重 Weight | t | 10 |