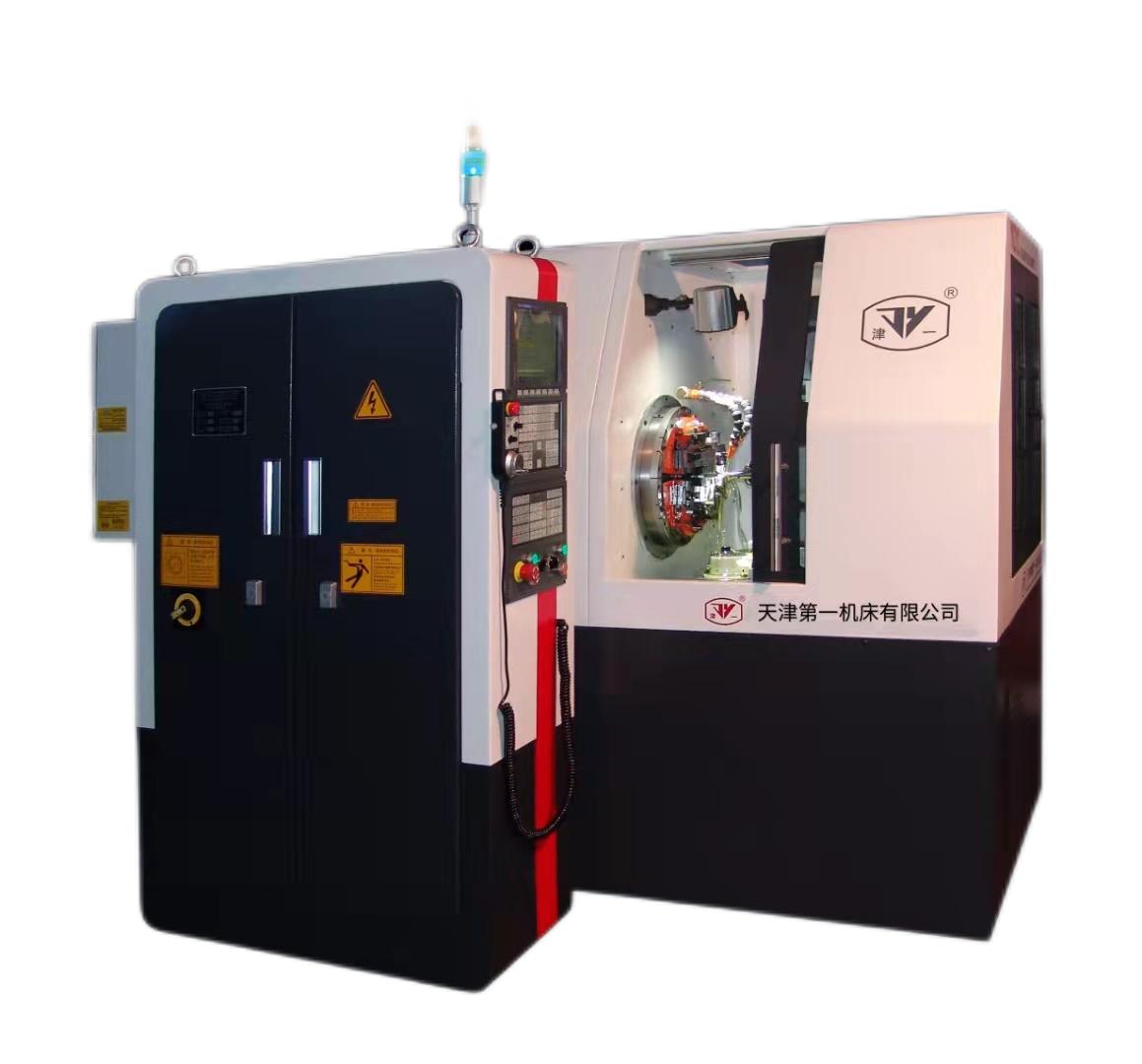

YK2312CNC Straight Bevel Gear Generator

YK2312 CNC STRAIGHT BEVEL GEAR GENERATOR

The YK2312 CNC straight bevel gear generator is a newly developed product of Tianjin No.1 Machine Tool Co., Ltd. through its specialized technology and experience in building straight bevel gear generators for nearly 70 years. This machine is especially suitable for cutting high-precision straight bevel gears of small diameters and small modules. The accuracy of the straight bevel gears machined by this machine can reach Grade 6 of the GB Standard.

The machine cuts gears using two reciprocating cutters and all the single job production, small lot production and batch production are accommodated on this machine. It’s applicable for the manufacturing of small precision straight bevel gears used in the precision instrument and apparatus industries.

I. MACHINE FEATURES

1. This is a 4-axis CNC machine with 3-axis simultaneous movements. The spindle servo motor is the power source and tool setting and cutter adjustments can be made through the electronic handwheel.

2. After the conventional mechanical structure is simplified and the transmission chain is shortened, the machine set-up time is reduced as changes of the change gears are not required. This not only increases the machine accuracy but also makes the machine operation more correct and more convenient.

3. A GSK CNC control system and servo motors are the standard equipment of the machine. A SIEMENS or a FANUC CNC control system and motors can be available on special requests of the customer. A full-enclosure and a chip removal container are the standard equipment.

4. The machine has a free-standing sealed electrical cabinet equipped with a thermostatic- control device.

5. A built-in coolant tank and a hydraulic tank are erected on the machine bed.

II. SPECIFICATIONS

1.Dimensions of Work | ||

Max. module of work | mm | 2.5 |

Max. length of pitch element | mm | 63 |

Max. pitch diameter (ratio 10:1) | mm | 125 |

Root angle Max.90º & Min.4º | ||

Extreme ratio (at 90º shaft angle) | ratio | 10:1 |

Max. tooth depth | mm | 5.5 |

Max. face width | mm | 20 |

Number of teeth | teeth | 5 -- 150 |

2.Work Spindle | ||

Diameter of taper hole at large end | mm | Φ31.267 |

Taper | ratio | Morse No.4 |

Taper length | mm | 80 |

Diameter of through hole | mm | Φ20H11 |

Distance from face of spindle to machine center | mm | 30 -- 190 |

3.Cutter Head | ||

Adjusting angle | degree | 360º |

Max. cradle roll | degree | 80º |

Max. positioning angle of tool holder | degree | 8º |

Max. travel of cutter | mm | 28 |

Over run of cutter | mm | 3 at inner end 5 at outer end |

4.Cutter | ||

Type GR83-60I straight bevel gear cutter | I | |

Cutter strokes per minute | str./min | 250-- 700 |

5.Voltage | v | 380 |

6.Machine Weight | t | 1.8 |

7.Overall Dimensions | mm | 1700x1650x1700 |